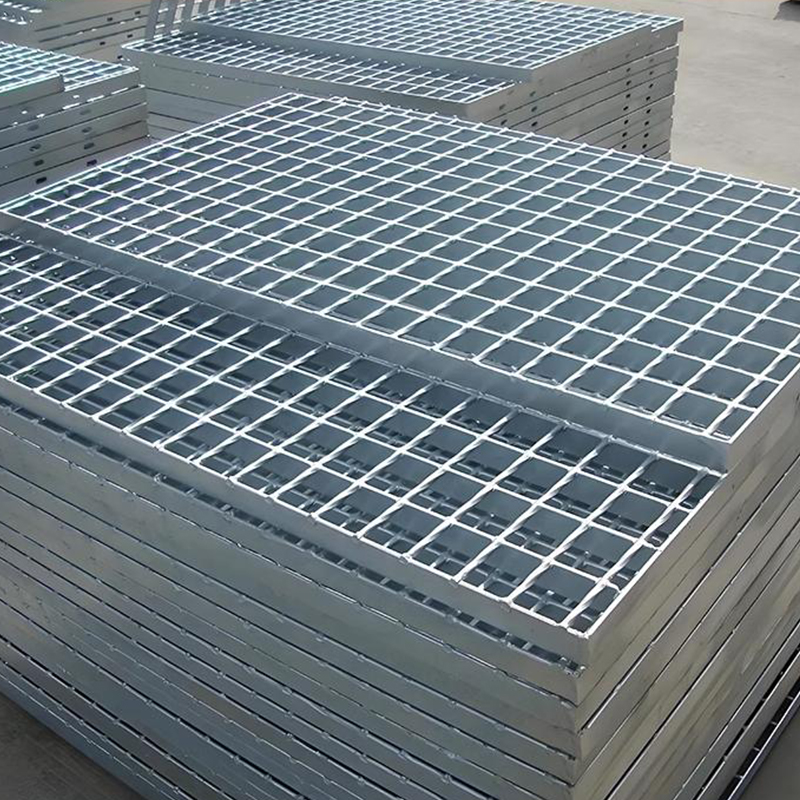

Stainless steel grating—a metal building material with a high-quality carbon steel skeleton and a zinc coating—is shining brightly in industrial platforms, municipal facilities, commercial spaces, and even high-end building facades, thanks to its superior

- +86-15369906288

- 53832521@qq.com

- 100 meters east of Hecao Village, Anping County